Zhiyang Machinery

Zhiyang Machinery

0519-88674267/88674627

czzy2015@vip.163.com

No. 113 Huanzhen Road

Search The Product

Search The Product

Products

Products

Product description:

Product description:

● Spray drying is the most widely used process in the liquid process forming and drying industry. Most suitable for producing powdery, granular solid products from solutions, emulsions, suspensions and pasty liquid raw materials. Therefore, when the particle size distribution, residual moisture content, bulk density and particle shape of the finished product must meet precise standards, spray drying is an ideal process.

Working principle:

● After filtering and heating, the air enters the air distributor at the top of the dryer, and the hot air enters the drying chamber uniformly in a spiral shape. The material liquid is sprayed (rotated) into ultra-fine mist-like liquid beads through a high-speed centrifugal atomizer on the top of the tower body, and can be dried into a finished product in a very short time in contact with hot air in parallel. The finished product is continuously output from the bottom of the drying tower and the cyclone, and the exhaust gas is evacuated by the fan.

Drying characteristics:

● The drying speed is fast, and the surface area of ??the material liquid is greatly increased after being atomized. In the hot air current, 95% -98% of water can be evaporated in an instant. The drying time is only a few seconds. It is especially suitable for drying heat-sensitive materials.

● The product has good uniformity, fluidity and solubility, high purity and good quality. The production process is simplified and the operation and control are convenient. For liquids with a moisture content of 40-60% (special materials can reach 90%), they can be dried into powder products at one time, without crushing and screening after drying, reducing production processes and improving product purity. The product particle size, bulk density, and moisture can be adjusted by changing the operating conditions within a certain range, and the control and management are very convenient.

Application:

● Chemical industry: sodium fluoride (potassium), basic dye pigment, dye intermediate, compound fertilizer, formaldehyde silicic acid, catalyst, sulfuric acid agent, amino acid, white carbon, etc

● Plastic resin: AB, ABS emulsion, urethane resin, phenolic resin, dense (urea) formaldehyde resin, polyethylene, polyvinyl chloride, etc.

● Food industry: fat-rich milk powder, tickle, cocoa milk powder, milk substitute powder, blood hunting powder, egg white (yellow), etc.

● Food and plants: oats, chicken juice, coffee, instant tea, flavoured meat, protein, soybean, peanut protein, hydrolysate, etc.

● Sugars: corn pulp, corn starch, glucose, pectin, maltose, potassium sorbate, etc.

● Ceramics: alumina, tile materials, magnesia, talc, etc.

| Item Parameter Model |

LPG |

|||||

|

5 |

25 |

50 |

100 |

150 |

200-2000 |

|

|

Inlet temperature ℃ |

140-350 automatic control |

|||||

|

Outlet temperature ℃ |

~80-90 |

|||||

|

Maximum evaporation of water kg/h |

5 |

25 |

50 |

100 |

150 |

200-2000 |

|

Centrifugal spray head drive form |

Compressed air transmission |

Mechanical transmission |

||||

|

Rotating speed (rpm) |

25000 |

18000 |

18000 |

18000 |

15000 |

8000-15000 |

|

Spray plate diameter (mm) |

50 |

100 |

120 |

140 |

150 |

180-340 |

|

Heat source |

Electricity |

Electricity + steam |

Electricity + steam, fuel, gas |

Solved by the user |

||

|

Electric heating maximum power (kw) |

9 |

36 |

63 |

81 |

99 |

|

|

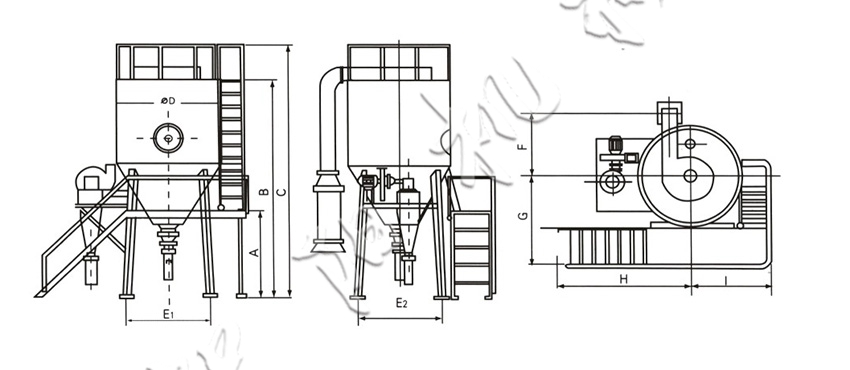

Dimensions L * W * H (m) |

1.8×0.93 |

3×2.7 |

3.7×3.2 |

4.6×4.2 |

5.5×4.5 |

Solve it according to the specific |

|

Dry powder recovery (%) |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

≥95 |

All data is for reference only. Depending on the material, the company has the right to change without notice.

Follow Us

Follow Us