Zhiyang Machinery

Zhiyang Machinery

0519-88674267/88674627

czzy2015@vip.163.com

No. 113 Huanzhen Road

Search The Product

Search The Product

Products

Products

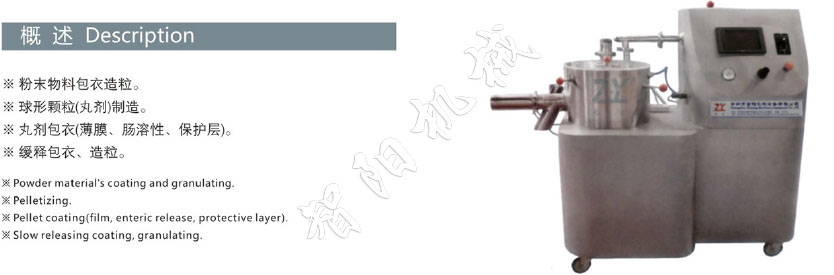

Working principle:

Working principle:

● The powdery material forms a three-dimensional circular motion under the action of the centrifugal force, frictional force of the turntable, and the buoyancy of the annulus gas, sprays an appropriate amount of atomized slurry, and the powders gather together into fine particles to complete the "mother" process. After the dried and sieved master batch is injected, the atomized slurry is sprayed and the powder is added. The master batch is enlarged on this basis, and spherical pellets with high true sphericity can be obtained after a certain time. Put the finished pellets into the material tank and spray an appropriate amount of atomized coating liquid to form a uniform and continuous coating film.

Features:

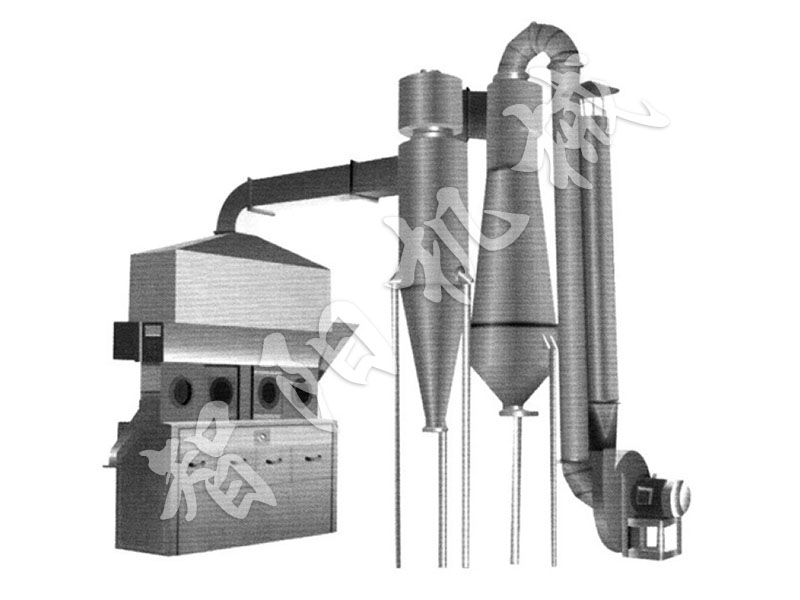

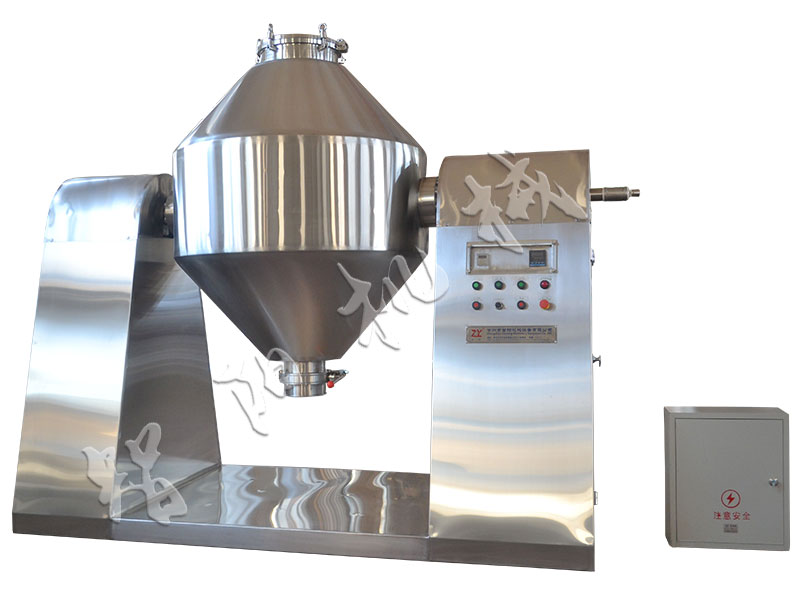

● This machine is composed of air intake processing system, host system, spray system, powder feeding mechanism, and air exhaust system.

● It integrates the functions of "raising mother", "granulation" and "coating".

● Unique spoiler block and spoiler to improve the material trajectory and increase the rate of qualified products.

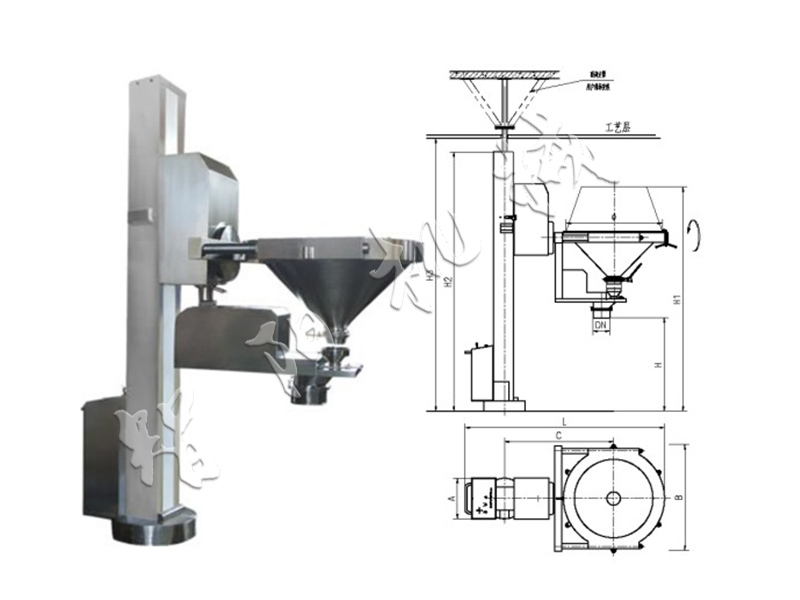

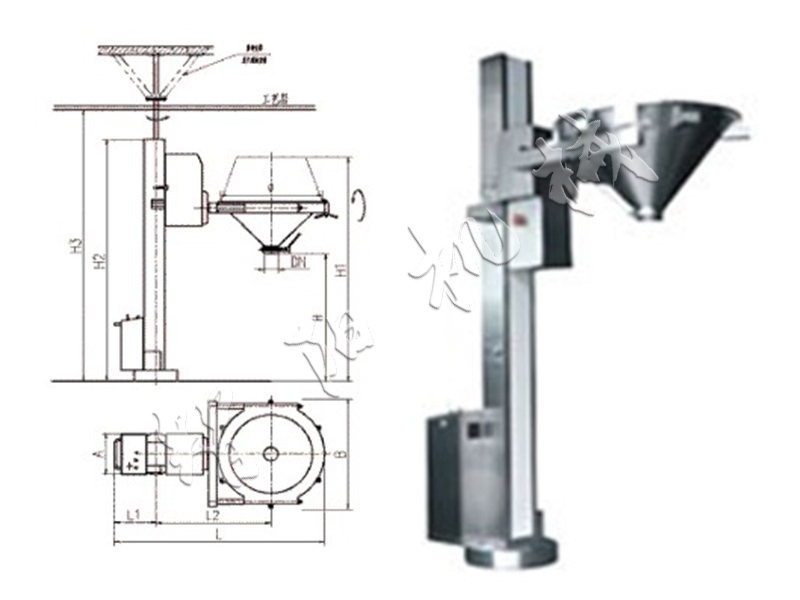

● Screw-type powder feeder, equipped with a bridge-breaking stirring device, continuously feeding powder.

● Manual screw lifter lifting device, accurate positioning, safe and reliable.

● Touch screen + PLC control system, stepless speed regulation by inverter.

● Perfect interlocking protection measures.

● Only need to change different turntables (optional), it can be matched with the extruder to carry out the extrusion-spheronization process operation.

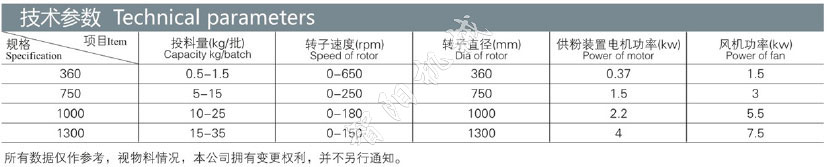

| Project type |

BZJ-360 |

BZJ-700 |

BZJ-1000 |

||

|

Minimum feeding amount (blank grain) |

KG |

0.5 |

2.0 |

5.0 |

|

|

Rated output (blank grain) |

KG/batch |

≤2.5 |

≤20.0 |

≤50.0 |

|

|

Gain |

-- |

≤2 |

|||

|

Pellet diameter |

mm |

Φ0.25-20 |

|||

|

Turntable diameter |

mm |

350 |

700 |

1000 |

|

|

Monitor rate |

KW |

1.1 |

7.5 |

7.5 |

|

|

Blower power |

KW |

0.2 |

2.2 |

4 |

|

|

Induced fan power |

KW |

0.2 |

1.5 |

2.2 |

|

|

Electric heating |

KW |

1.8 |

2.4 |

5.5 |

|

|

Rotating speed |

R/min |

50-1400 |

50-1200 |

50-500 |

|

|

Compressed air |

Pressure |

Mpa |

0.4-0.6 |

||

|

Consumption |

M3/min |

0.3 |

0.9 |

1.1 |

|

|

Inlet air temperature |

℃ |

Δt=80℃,Automatic adjustment Δt=80℃ |

|||

|

Noise |

db |

<60 |

<65 |

<65 |

|

|

Host Dimensions (L×W×H) |

mm |

1000×620×1700 |

1500×900×1300 |

2300×1200×1350 |

|

|

Net Weight |

kg |

180 |

700 |

1800 |

|

All data are for reference only, depending on the material, the company has the right to change without notice

Follow Us

Follow Us