Zhiyang Machinery

Zhiyang Machinery

0519-88674267/88674627

czzy2015@vip.163.com

No. 113 Huanzhen Road

Search The Product

Search The Product

Products

Products

Purpose:

Purpose:

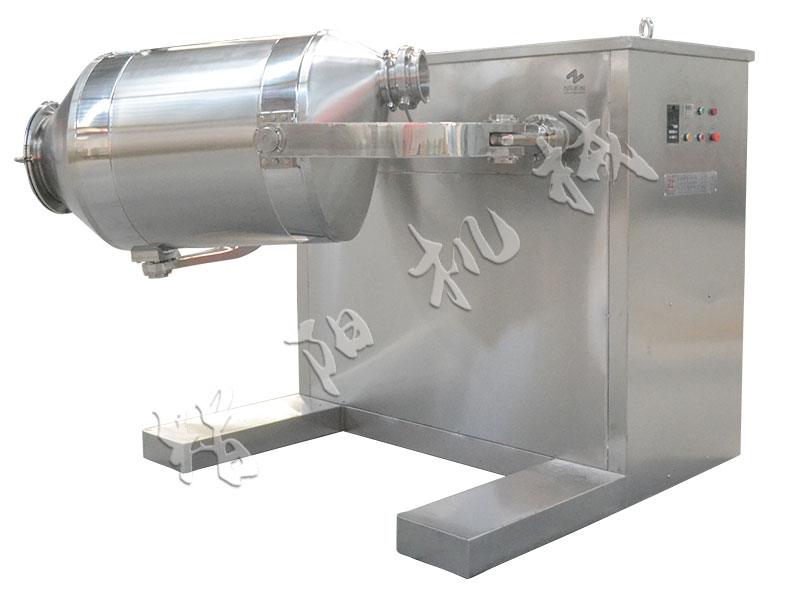

● The machine can automatically complete all actions such as lifting, clamping, mixing, and lowering. Equipped with an automatic lifting hopper mixer and multiple mixing hoppers of different specifications, it can meet the mixing requirements of large quantities and varieties, and it is the ideal equipment for the general mixing of pharmaceutical factories. At the same time widely used in pharmaceutical, chemical, food and other industries.

Principle:

● The machine consists of a base, a slewing body, a drive system, a hoisting system, a braking system and a control system. When working, push the mixing hopper into the rotating body, and press the "OK" key on the touch screen to automatically lift the mixing hopper into place and clamp it automatically. After the pressure sensor receives the clamping signal, the drive system works and mixes according to the set time and speed; after the set parameters are reached, the swing body can automatically stop vertically and the braking system works at the same time, and the mixing ends; then the system works. The mixing hopper in the rotating body is lowered into place, automatically stopped, and the process data is printed. Push the mixing hopper out to the next process.

Features:

● This machine is a new model that our company has absorbed and digested advanced foreign technology, combined with national conditions. The structure is reasonable, the performance is stable, the operation is convenient, and the whole machine has no dead corners and no exposed screws. The rotating body (mixing hopper) forms an angle of 30 ° with the axis of rotation. The material in the mixing hopper is turned along with the rotating body, and at the same time, it makes tangential movement along the bucket wall, resulting in strong overturning and high-speed tangential movement to achieve the best Blending effect. It adopts PLC full automatic control and is equipped with infrared safety device and discharge butterfly valve to prevent misoperation to ensure production safety. The materials can pass through different process sections in the same container, and there is no need to frequently transfer and add materials. Effectively control dust and cross-contamination, reduce the loss of materials, control the layering of materials, optimize the production process, and fully meet the GMP requirements of pharmaceutical production.

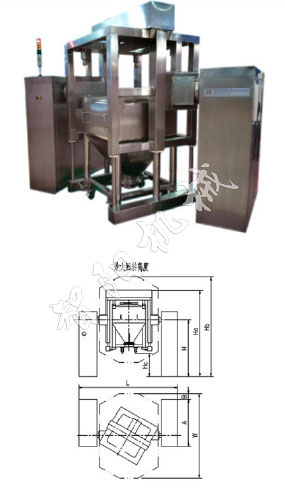

|

Model |

Host structure size |

Net Load |

Mixed Speed |

Machine Weight |

||||||||

|

L |

A |

B |

W |

H |

Ha |

Hb |

Hc |

Volume (L) |

Weight (kg) |

Rpm |

Kg |

|

|

HZD-400 |

2650 |

1200 |

275 |

2270 |

1670 |

2450 |

2810 |

720 |

320 |

240 |

3-20 |

1.8 |

|

HZD-600 |

2800 |

1300 |

300 |

2400 |

1570 |

2520 |

2770 |

720 |

480 |

360 |

3-15 |

2 |

|

HZD-800 |

3000 |

1400 |

240 |

2600 |

1730 |

2640 |

2810 |

720 |

640 |

480 |

3-15 |

2.4 |

|

HZD-1000 |

3300 |

1400 |

400 |

2760 |

1760 |

2760 |

3140 |

720 |

800 |

600 |

3-15 |

2.8 |

|

HZD-1200 |

3400 |

1400 |

420 |

2860 |

1820 |

2800 |

3250 |

720 |

960 |

720 |

3-15 |

3 |

|

HZD-1500 |

3400 |

1400 |

430 |

3040 |

1930 |

3110 |

3450 |

720 |

1200 |

900 |

3-15 |

3.5 |

|

HZD-1800 |

3560 |

1600 |

450 |

3200 |

1960 |

3180 |

3560 |

720 |

1440 |

1080 |

3-15 |

3.6 |

|

HZD-2000 |

3560 |

1600 |

450 |

3300 |

2080 |

3380 |

3880 |

720 |

1600 |

1200 |

3-15 |

4 |

Follow Us

Follow Us