Zhiyang Machinery

Zhiyang Machinery

0519-88674267/88674627

czzy2015@vip.163.com

No. 113 Huanzhen Road

Search The Product

Search The Product

Products

Products

Application:

● This machine is mainly used for the mixing of granules and granules, granules and powders, powders and powders in the solid preparation of pharmaceutical industry. It has the advantages of large mixing batch, reliable load, stable operation and so on. It is the ideal equipment for the general mixing of pharmaceutical factories. At the same time widely used in pharmaceutical, chemical, food and other industries.

Principle:

● This machine is composed of machine base, drive system, control system, mixing hopper and other components. During work, after adding the material to the hopper, lock the hopper lid, set the mixing time and mixing speed according to the process requirements, and start the control system to start the mixing operation; after the set time, the machine will automatically stop and perform after the mixing is completed. Dosing.

Features:

● This machine is a new model that our company has absorbed and digested advanced foreign technology, combined with national conditions. The structure is reasonable, the performance is stable, the operation is convenient, and the whole machine has no dead corners and no exposed screws. And set the butterfly valve of the anti-misoperation device to ensure production safety. The rotating body (mixing hopper) forms an angle of 30 ° with the axis of rotation. The material in the mixing hopper is turned along with the rotating body, and at the same time, it makes tangential movement along the bucket wall, resulting in strong overturning and high-speed tangential movement to achieve the best The mixing effect optimizes the production process and fully meets the GMP requirements for pharmaceutical production.

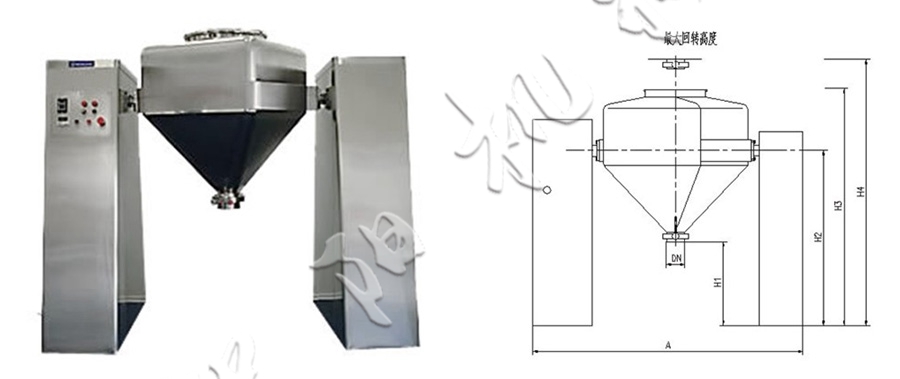

Technical Parameters:

|

Main structure size |

Net load |

Mixed Speed |

Machine Weight |

Total Power |

|||||||||

|

A |

B |

C |

DN |

H1 |

H2 |

H3 |

H4 |

容积L |

重量kg |

rpm |

T |

kw |

|

|

HGD-200 |

1700 |

1000 |

650 |

150 |

700 |

1270 |

1580 |

1810 |

160 |

100 |

3-20 |

0.5 |

1.1 |

|

HGD-300 |

2000 |

1100 |

750 |

150 |

700 |

1300 |

1700 |

1860 |

240 |

150 |

3-20 |

0.6 |

1.5 |

|

HGD-400 |

2000 |

1200 |

800 |

150 |

750 |

1460 |

1860 |

2170 |

320 |

200 |

3-20 |

0.7 |

1.5 |

|

HGD-600 |

2280 |

1300 |

900 |

150 |

750 |

1450 |

2000 |

2200 |

480 |

300 |

3-20 |

0.9 |

2.2 |

|

HGD-800 |

2380 |

1300 |

1000 |

200 |

750 |

1550 |

2080 |

2380 |

640 |

400 |

3-20 |

1 |

2.2 |

|

HGD-1000 |

2600 |

1400 |

1100 |

200 |

750 |

1650 |

2200 |

2550 |

800 |

500 |

3-20 |

1.2 |

3 |

|

HGD-1200 |

2900 |

1400 |

1200 |

200 |

750 |

1650 |

2300 |

2650 |

960 |

600 |

3-15 |

1.4 |

4 |

|

HGD-1500 |

3000 |

1400 |

1300 |

200 |

750 |

1720 |

2300 |

2700 |

1200 |

750 |

3-15 |

1.6 |

4 |

|

HGD-2000 |

3150 |

1500 |

1400 |

200 |

750 |

1820 |

2470 |

2900 |

1600 |

1000 |

3-12 |

2 |

5.5 |

|

HGD-2500 |

3300 |

1500 |

1500 |

200 |

750 |

1900 |

2600 |

3050 |

2000 |

1250 |

3-12 |

2.5 |

5.5 |

|

HGD-3000 |

3600 |

1700 |

1600 |

250 |

750 |

2130 |

2780 |

3500 |

2400 |

1500 |

3-12 |

2.8 |

7.5 |

|

HGD-4000 |

3800 |

1800 |

1700 |

250 |

1000 |

2430 |

3250 |

3720 |

3200 |

2000 |

3-12 |

3.2 |

7.5 |

|

HGD-5000 |

4300 |

2000 |

2000 |

250 |

1000 |

2560 |

3400 |

4200 |

4000 |

2500 |

3-12 |

3.8 |

11 |

|

HGD-6000 |

4400 |

2000 |

2100 |

250 |

1000 |

2630 |

3600 |

4260 |

4800 |

3000 |

3-8 |

4.5 |

11 |

|

HGD-8000 |

4600 |

2200 |

2200 |

250 |

1000 |

2650 |

3700 |

4350 |

6400 |

4000 |

3-8 |

5.2 |

15 |

|

HGD-10000 |

4860 |

2200 |

2350 |

250 |

1000 |

2800 |

3950 |

4600 |

8000 |

5000 |

3-8 |

6.5 |

15 |

All dimensions are for reference only. Depending on the material, the company has the right to change without notice.

Follow Us

Follow Us